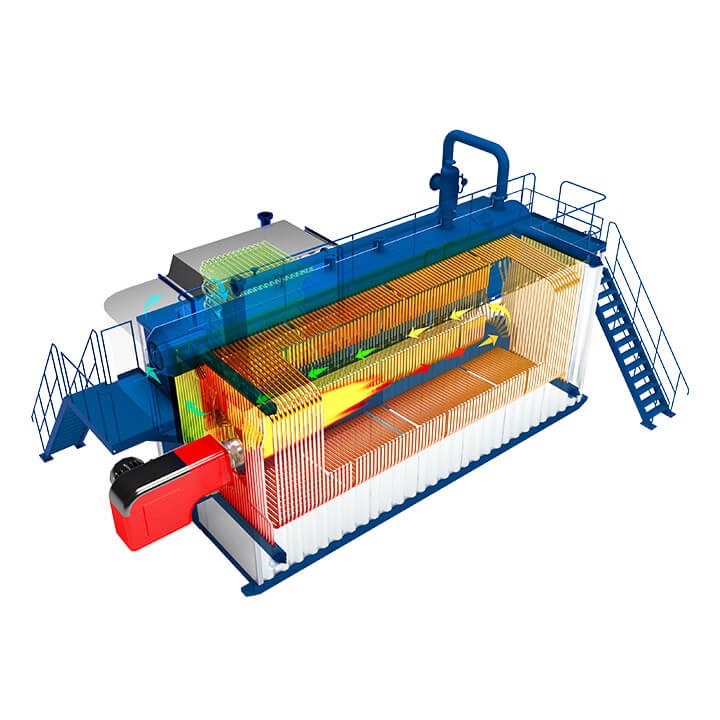

The Gas(oil) Fired Water Tube Hot Water Boiler is a double-drum longitudinal “D” type structure. The water, steam, or steam-water mixture flows in the tubes. The flame burns and the flue gas flows outside the tubes, to ensure a good water circulation system, thus ensuring the long-term stable operation of the boiler.

InquiryThe boiler adopts a countercurrent arrangement, the furnace volume is selected reasonably, and the fuel is fully combusted.

The Gas(oil) Fired Water Tube Hot Water Boiler uses gas (oil) fuel, which has a low vaporization rate and a strong ability to protect the boiler.

Aluminum silicate felt and ultra-fine glass wool insulation material with a total thickness of 200mm, the heat loss of the Gas(oil) Fired Water Tube Hot Water Boiler is minimized.

The Gas(oil) Fired Water Tube Hot Water Boiler is designed and assembled with a short installation period and convenient disassembly for post-maintenance and inspection.

Gas(oil) Fired Water Tube Hot Water Boiler Rated thermal power: 10.5-70Mw

Gas(oil) Fired Water Tube Hot Water Boiler Rated thermal efficiency: 95-98%

Gas(oil) Fired Water Tube Hot Water Boiler Pressure: ≤2.5MPa

Gas(oil) Fired Water Tube Hot Water Boiler Available fuel: natural gas, city gas, LPG, etc.

Full-membrane wall structure

Furnace wall tube adopts full membrane wall, which makes furnace body have good sealing structure. Under the micro-positive pressure combustion state, the boiler operation won’t cause the phenomenon of smoke leakage or air leakage.

The economizer can not only absorb the sensible heat in the flue gas but also absorb the sufficient latent heat, which makes the Gas(oil) Fired Water Tube Hot Water Boiler much more efficient than the ordinary boiler.