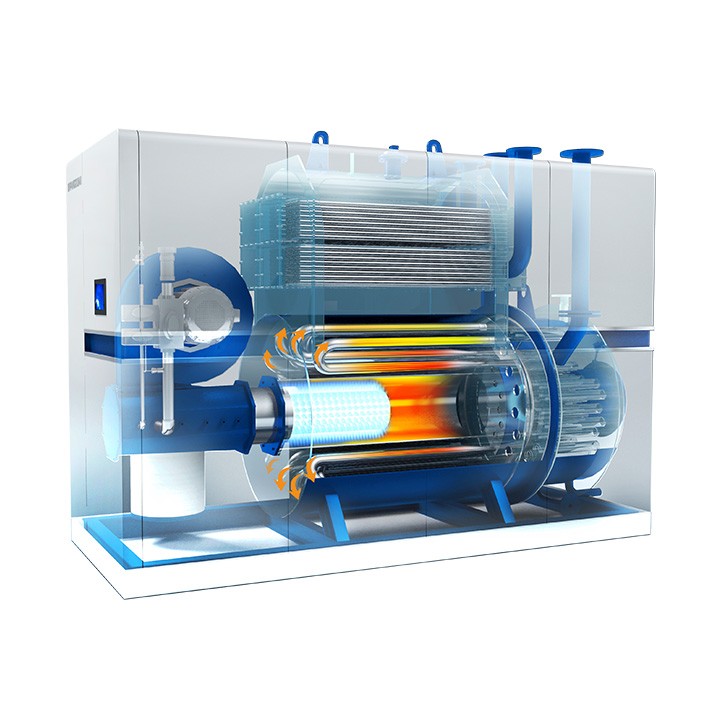

The T6 Vacuum Hot Water Boiler adopts an environmentally friendly combustion method – full premixed combustion, and the gas and air are precisely adjusted and premixed in advance to ensure more complete combustion. The new crossing wing-shaped heat exchange element, Ultra-speed Smoke Cooking Tube, uses a unique heat transfer technology and structural design to achieve deep condensation of flue gas and greatly improve heat transfer efficiency.

InquiryThe heat exchange surface of the boiler is sufficient, and the condenser and the rear smoke box are integrated to reduce the total volume of the boiler.

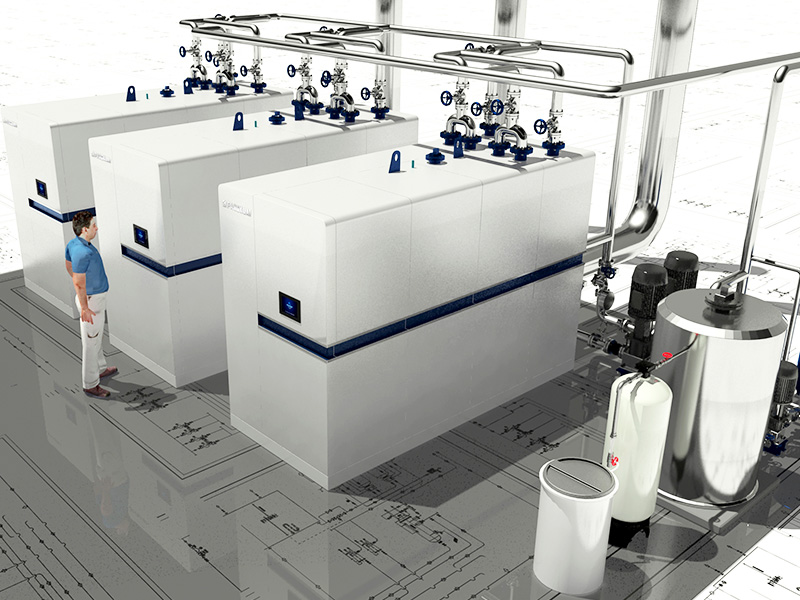

The T6 Vacuum Hot Water Boiler adopts a standard pipe box, adapts to the single and double circuits, different temperatures, and other modes, and realizes a multi-channel water supply.

The flow rate of the flue gas in each section is stable, and the utilization rate of the heat exchange surface is improved.

The heat medium in the T6 Vacuum Hot Water Boiler is deoxidized and descaled, and there will never be scaling and corrosion. The normal service life can reach more than 20 years.

T6 Vacuum Hot Water Boiler Rated thermal power: 0.7-2.8Mw

T6 Vacuum Hot Water Boiler Rated thermal efficiency: 105.5%

T6 Vacuum Hot Water Boiler Pressure: -0.02MPa

T6 Vacuum Hot Water Boiler Available fuel: natural gas

Full premixed combustion

The fuel and air are precisely adjusted to achieve a good match to ensure more complete combustion; surface combustion technology makes combustion more efficient and reduces harmful emissions.

The new crossing wing-shaped heat exchange element, Ultra-speed Smoke Cooking Tube, is made of aluminum-silicon alloy with high thermal conductivity, which greatly extends the service life of the pressure components.